The Franklin AFC5108 CNC Angle machine is one of the most versatile rugged built machines available. The Unique Dual Shear die set allows two (2) Shear dies to be interchanged in the same machine, unlike any other machine on the market.

The Standard AFC5108 provides 8x8x ¾” Double-cut capacity and 6x6 x ½” Single-cut capacity in the same machine.

Programmable triple gag tooling allows the press to hold three different punch sizes. All Franklin fabricators have various material handling devices including automatic loading systems and outfeed kickoff conveyors. Optional plasma cutting offers complete integrated cutting systems with dual position capability on both legs of the angle.

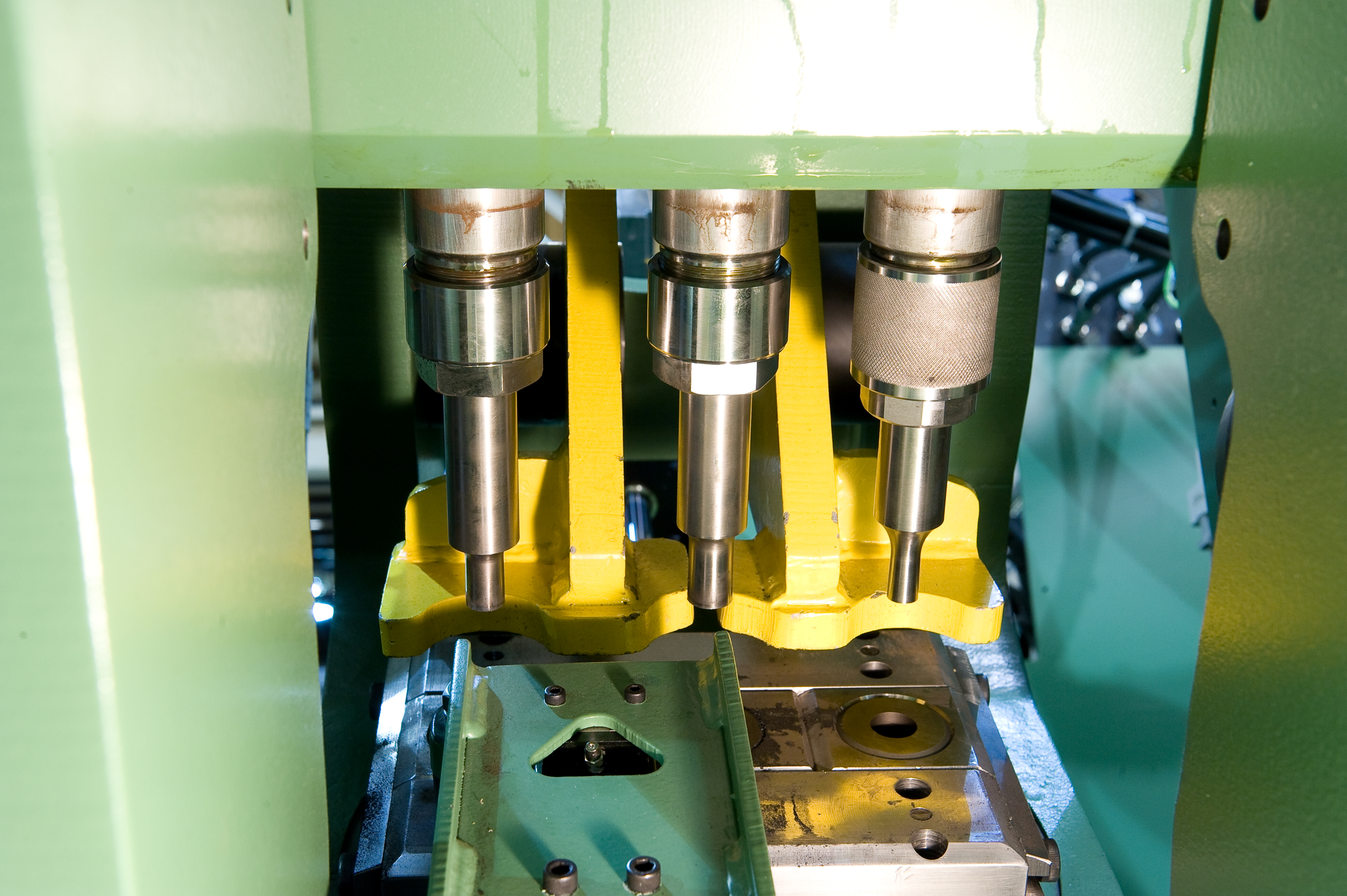

The optional Triple Gag Tooling System provides three (3) preloaded tools of different sizes or shapes. All units are manufactured from a Ductile Iron material for high tonnage capacity. The tooling assembly is side supported by heat treated gib plates. Lower die blocks with "Quick Change" slide out features allowing fast tool changes and also acts as a replacement unit. Pneumatic gags with switch detection provide the CNC controls positive tool selection. Each gag assembly has a lubricated air blast that lubricates the punch road and maintains positive air pressure on top of the floating punch stem.

Outfeed Conveyor SystemWith automatic kickoff sequencing, material is conveyed with solid heat treated vee-rolls powered with AC servo drives. Optional lengths from 20 to 120 ft are available |

|

|

Hydraulic SystemsBeing built and designed by Franklin, they provide both speed and power. The vertical tank design consumes little floor space, and is easy to maintain. The following capacities are available: 20 or 40 HP, Air Cooler Standard, 32 or 46 GPM, 10 Micron Filtration, 120 Gallon tank - pressure comp. Piston Pump with HPL and 3 stage pressure control. |

Dual Axis CNC PlasmaWith 200 amp cutting capacity, the MaxPro 200 or optional HPR Oxygen Plasma integrated into the Franklin CNC Angle system provides completed parts in one operation. Standard cut profiles include notches, bevels, miters, circles, squares, and copes. |

|

|

|

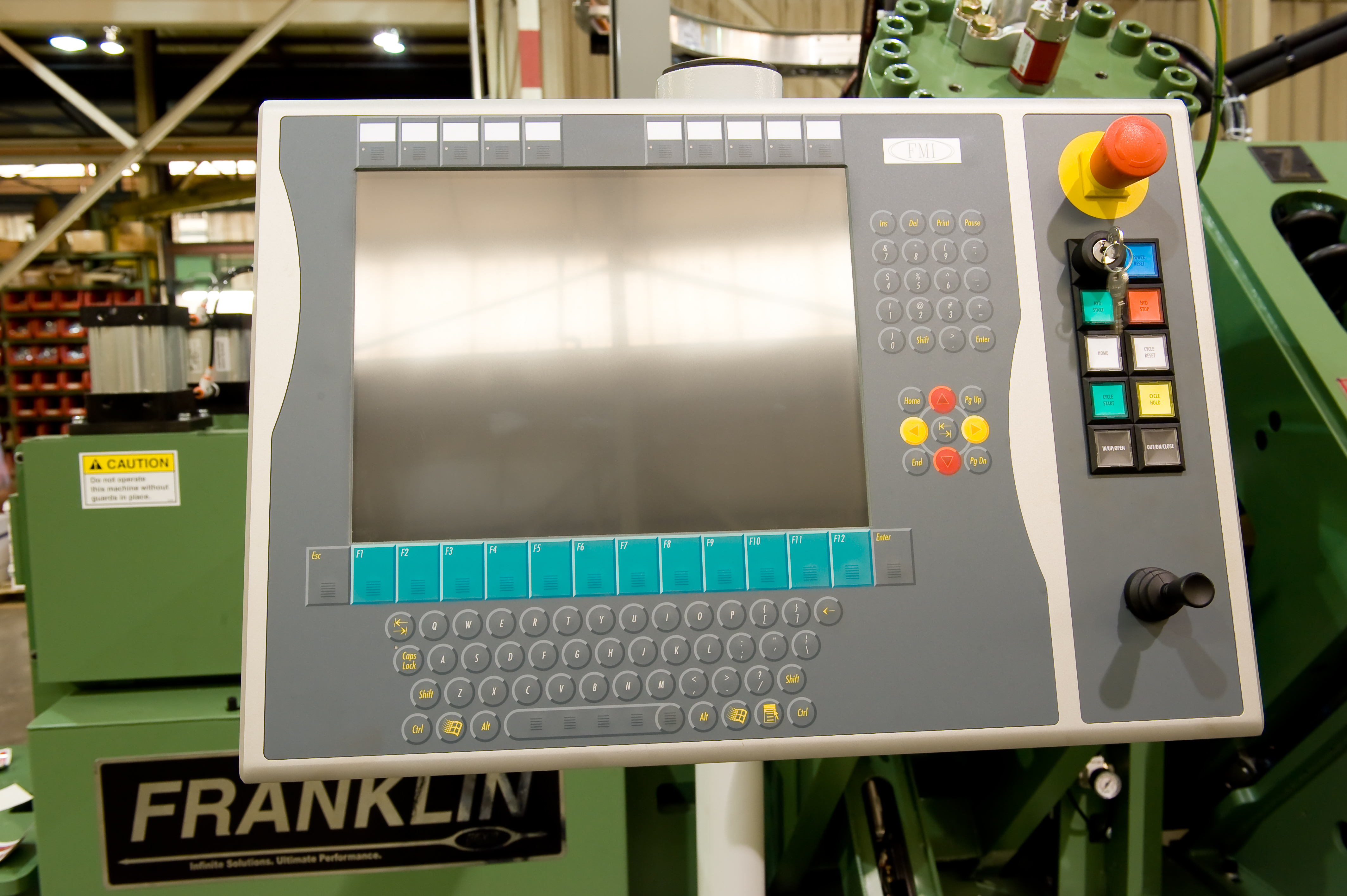

CNC ControlsThe controls are build within the Windows operating system. Simple user friendly programming, with exclusive software features, design and developed by Franklin for each machine's application. |

Dual Station Die TableThe flexibility of switching from a single cut die set to a double cut die set is a 1 - 2 minute process. |

|

|

Triple Gag ToolingThe Tooling provides 3 preloaded tools of different sizes or shapes. All units are manufactured from a Ductile Iron material for high tonnage capacity. The tooling assembly is side supported by heat treated gib plates. Lower die blocks with quick changes slide out features allowing fast tool changes and also acts as a replacement unit. Air operated gags with switch detection provide the CNC controls positive tool selection. Each gag assembly has a lubricated air blast that lubricates the punch rod and maintains positive air pressure on top of the Floating Punch Stem. |

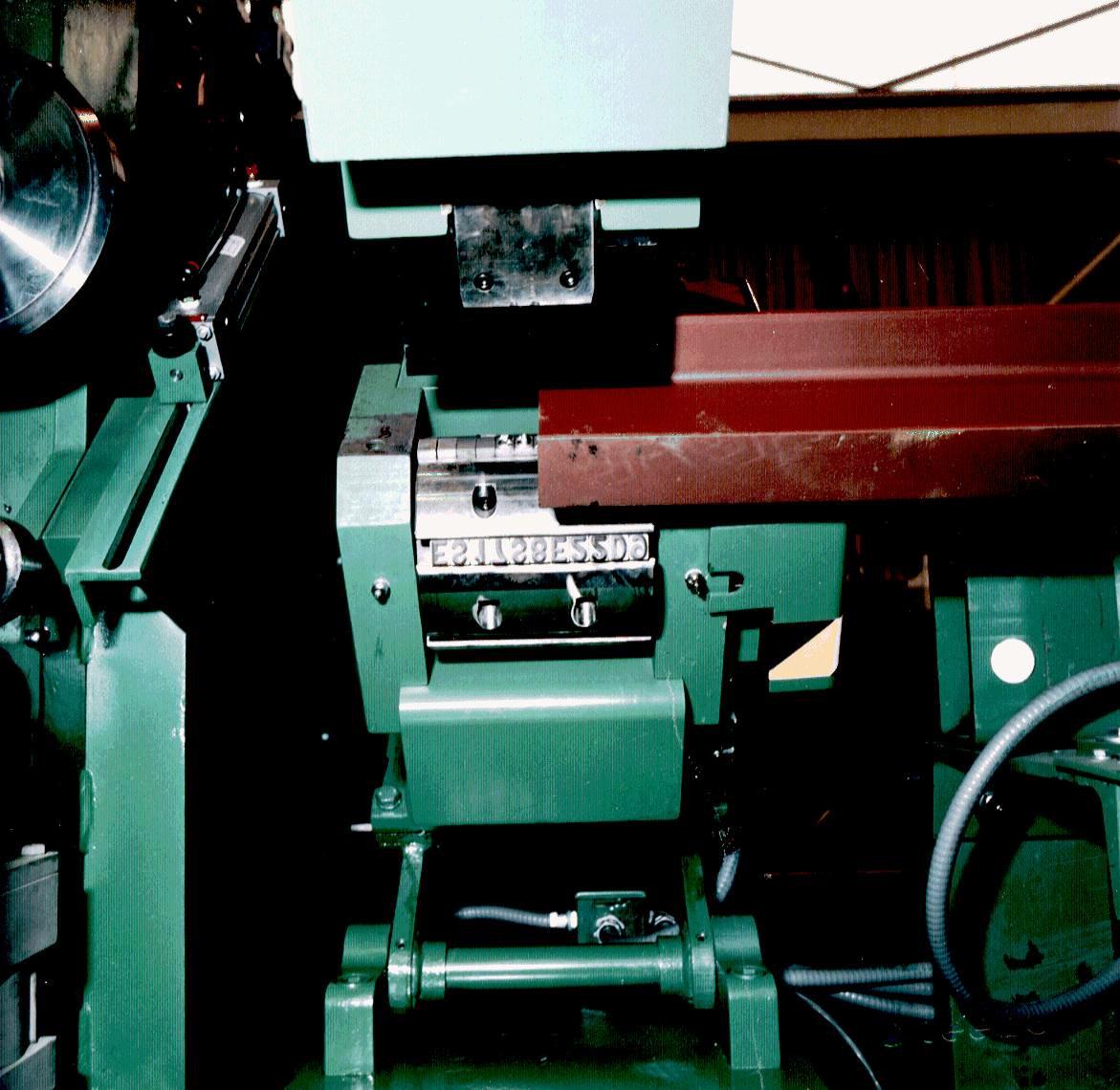

Hydraulic Ram StencilerThis is for deep imprint marking. 6 position CNC rotating turret with 10 each 5/8" characters. Optional ID and marking options: High speed dot matrix marking, Inkjet marking, Bar code label printer applicator with code 39 format. |

|

|

|

High Speed StencilerThis is for deep marking capabilities that can be galvanized. The integrated marking system is driven by the Franklin CNC control by providing markings without moving the material. |

Servo CarriageFeed system with an extremely accurate AC closed loop positioning servo. The heavy duty 8./00" x 1.250" precision ground track provides 2 separate racks for driving and measuring. The encoder feed-back device accomplishes absolute positioning in the X-axis of +/- .005". |

|

|

|

Automatic Loading SystemAutomatically deposits each piece of stock onto the infeed conveyor. The ALS can store up to 14 pieces of 20-40ft stock for complete automatic sequencing. Bundle break down platforms at the rear of the transfer allows the operator to safely sort material as the machine runs. |